The sand production line is suitable for applications in hydropower, building materials, highways, urban construction, etc. It can be used for aggregates and artificial sand making operations of hard limestone, granite, basalt, river pebbles, slag, etc. It is especially suitable for special construction fields such as highway surface layering, high-grade road pavement gravel, high-speed railway passenger line sand and gravel aggregate, hydropower station sand and gravel material, port terminal and crushed stone for airport runway.

Process introduction

Production: 300-350 tons of limestone sand production line

| Configuration list | ||

| Equipment | Type | Number |

| Vibrating feeder | GZD1300×4900 | 1station |

| Jaw crusher | PE-900×1200 | 1station |

| Circular vibrating screen | 3YZS2460 | 1station |

| VSI Sand Making Machine | VSI-9526 | 1station |

| Circular vibrating screen | 3YKS2460 | 1station |

When producing 300-350 tons of limestone sand making equipment, the stone material is blasted from the mountain, and the stone material of less than 750mm is sent to the vibrating feeder through the dump truck. The vibrating feeder sends the stone material into the jaw crusher evenly, and the jaw crusher The machine will crush the stone in the first stage. The stone material from the smashing is about 95mm— 165mm. It is sent to the European version through the belt conveyor to break the second stage. The material of more than 40mm is returned to the counter-shock through the circular vibrating screen. Broken, the stone below 40mm is sent to the sand making machine. Finally, the material is graded and sieved through the circular vibrating screen. The material larger than the finished product is returned to the sand making machine for re-crushing, and the finished product is transported by the belt conveyor to the finished product area.

Note: When the feeding is in the range of 40mm--300mm, the material directly enters the European version to break the broken, without the first stage of the previous crushing. When the material is less than 40mm, it directly enters the sand making machine to break, without the first stage of the crushing and The second stage is broken.

Production: 200-250 tons granite sand production line

| Configuration list | ||

| Equipment | Type | Number |

| Vibrating feeder | GZD1100×4200 | 1station |

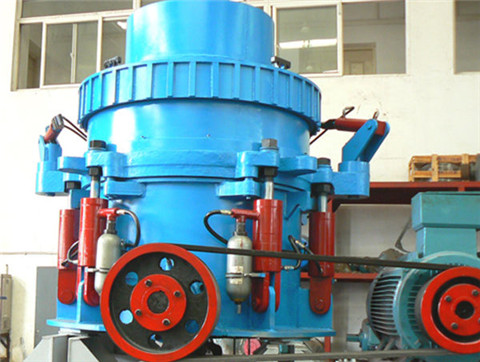

| Cone crusher | PSG2100 | 1station |

| Circular vibrating screen | 3YK2160 | 1station |

| VSI Sand Making Machine | VSI-1140 | 2station |

| Circular vibrating screen | 2YK2460 | 1station |

When producing 200-250 tons of river pebble sand making equipment, the stone material of less than 210mm is sent to the vibrating feeder through the dump truck. The vibrating feeder sends the stone uniform into the CS high efficiency spring cone crusher, and the cone is broken to the stone material. After a section of crushing, the return cone of more than 40mm is broken and broken by the circular vibrating screen, and the stone of 40mm or less is sent to the sand making machine. Finally, the finished material is sieved by the circular vibrating screen and transported by the belt conveyor to the finished product. Area.

Note: When the material is less than 40mm, it will directly enter the sand making machine and be broken without the first stage of the front.

Production: 150-200 tons of limestone sand production line

| Configuration list | ||

| Equipment | Type | Number |

| Vibrating feeder | GZD1100×4200 | 1station |

| Jaw crusher | PE-750×1060 | 1station |

| Impact crusher | PF1315 | 1station |

| Circular vibrating screen | 3YK2160 | 1station |

| VSI Sand Making Machine | VSI-1140 | 1station |

| Circular vibrating screen | 3YK2460 | 1station |

When producing 150-200 tons of limestone sand making equipment, the stone material is blasted from the mountain, and the stone material of less than 630mm is sent to the vibrating feeder through the dump truck. The vibrating feeder sends the stone material into the jaw crusher evenly, and the jaw crusher The machine will crush the stone in the first stage. The stone material from the smashing is about 80mm— 160mm. It will be sent to the European version through the belt conveyor to break the second stage. The stone will be returned to the counter-shock by the circular vibrating screen. Broken, the stone below 40mm is sent to the sand making machine. Finally, the finished material is sieved by the circular vibrating screen. The material larger than the finished product is returned to the sand making machine for re-crushing, and the finished product is transported by the belt conveyor to the finished product area.

Note: When the feeding is in the range of 40mm--300mm, the material directly enters the European version to break the broken, without the first stage of the previous crushing. When the material is less than 40mm, it directly enters the sand making machine to break, without the first stage of the crushing and The second stage is broken.